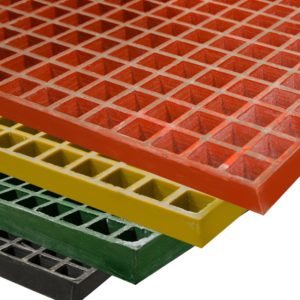

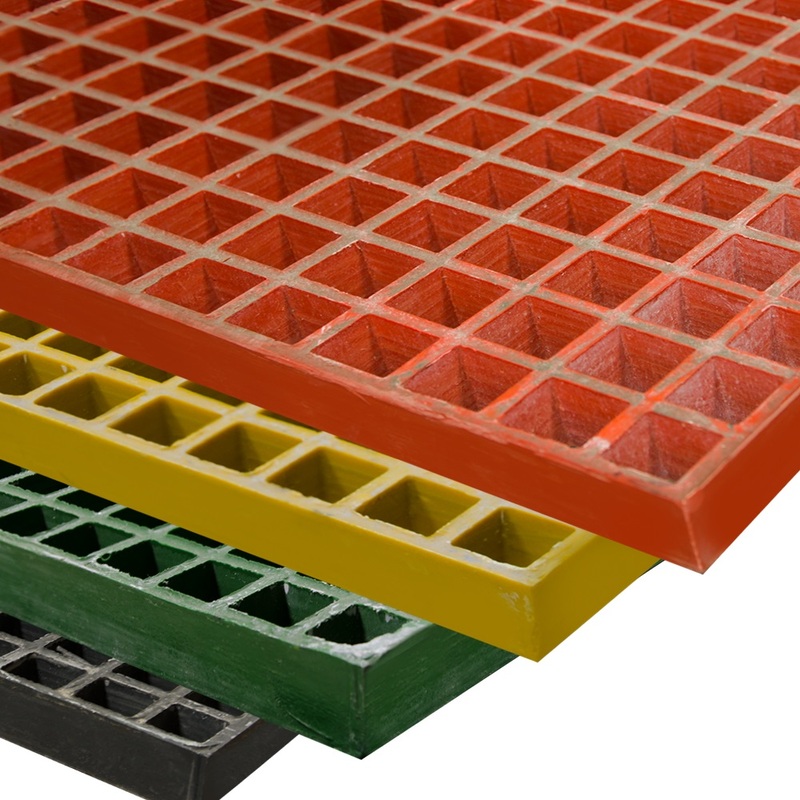

Today, pressed grating is the most common type of grating used in many countries. Its possibilities of use are almost unlimited thanks to a production technology clearly diverging from that of electroforged grating and allowing a much greater variety of models. The mesh configuration offers great flexibility, as well as the height and thickness of the support bars. The various materials that can be used for the manufacture of pressed slats allow to perfectly meet the wishes of the customer and the use for which the latter is intended for pressed slats. We do not claim that the pressed grating is the best grating that can exist but it is certainly the most beautiful and personalized, compared to the electro-forged grating. For the manufacture of pressed grating, the inserting bars, usually a cold-rolled plate, are pressed into the pre-stamped support bars. The frame is made in the form of a T-profile or a flat and is fixed by electrical welding. In case of slippery floors, pressed slats can be manufactured in a notched version. For this purpose, the upper surface of the support bars and/or the inserting bars is chipped. On pressed gratings, the meshes on the opposite ends are generally identical. But as has already been pointed out: when it comes to rushed grating, imagination and variety know no limits.

- Standard pebbles make boats safer

When we talk about standard grating, many people think first of fixed structures: buildings, factories, football stadiums. However, shipbuilding uses a lot of it. On a container ship, there are several tons of standardized grating and industrial grating. To allow crews to move around, stairs and walkways must meet very high safety requirements. All skid hazards must be excluded: with MEA slats, it is zero tolerance!

You would like to contact us for information, price, technical advice, quotation, etc.

- Perfect mesh for an aesthetic result

The advantage of MEA standardized grating lies in its perfectly flat surface and its harmonious and precise mesh. The arrangement of the meshes creates surface structures that provide a visual appearance that changes with the angle of vision and the angle of incidence of light. Standardized grating gives builders, architects and designers great creative freedom. It is for this reason that slats are increasingly used in urban architecture, in facade cladding or in sun protection.

- Standard grating: the U-profile makes the difference

Standard grating is a pressed grate with a U-shaped frame. The spacers are attached under high pressure in the split support bars. The high pressure and slit shape of the load bars guarantee the high resistance and torsional resistance of the grids.

Grating and frames are supplied separately.

Carrying bars of pressed grids distribute the load on supports. The spacers ensure the load distribution and guarantee the solidity of the grating.

If you would like to know more about our range of slats or if you are looking for a customized solution, do not hesitate to contact us.

Address: 134 Angle Route Ouled Ziane and Rue Aswane Immeuble B étage N° 3 , Casablanca 20250