Thanks to the assembly of support plates and galvanized steel spacers, the metal grating is a very resistant bending structure that can withstand loads. We offer slats with load bearing and transverse bars forming 30 mm mesh. Its grid-like appearance allows the passage of light. Ideal for your metal construction such as a terrace, a walkway or even a staircase. All these properties allow to use it in different ways as for the realization of a terrace, a bridge or even a staircase. However, be careful not to exceed 1.20 meters in length when used for pedestrians. The load-bearing direction determined by the load-bearing plates must be taken into account when installing the grating.

Designed for both exterior and interior fittings, metal grating offers high-performance technical qualities in terms of bending strength and load support. On the market, there are two types of designs: pressed steel grating and electroforged steel grating.

The main grating types

• Wooden grating: suitable for the manufacture of your wooden terrace, your bathroom.

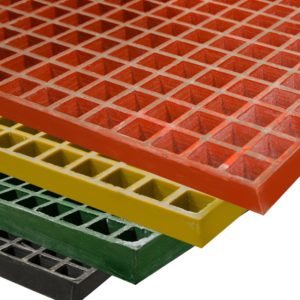

• Plastic grating: They are known for their non-slip properties.

• Steel grating: suitable for manufacturing your industrial floors.

What is the principle of metal grating?

The basic principle of a grating is an assembly of grid panels. More technically, the concept is based on the crossing of carrier plates and spacers that will come to draw a mesh. Depending on the use and configuration of the site, variations in the combination of height and thickness will determine the inertia of the whole. Depending on the expected purpose, technical or more aesthetic, the strength calculation of the crossing of the carrying bars and filling bars will define the mesh size. The perimeter of the grid ends with two types of finish, a flat iron edge or a U-shaped profile. To avoid oxidation of the steel and stainless steel that make them up, the metal grating will be treated by hot galvanizing. Then, a specific chemical treatment is applied depending on the environment and the purpose of the installation. This hot-dip galvanizing principle is obtained by a total dip in a molten zinc bath, once the steel is degreased and also stripped. Thus the grating will be hardened after contact with zinc and the protection will be both perfect and uniform on the entire surface. The galvanized metal guarantees a durable and reliable equipment, ideal for weather and weather hazards, especially for outdoor installations.

You would like to contact us for information, price, technical advice, quotation, etc.

Pressed or electroforged?

There are two main methods of manufacturing grating. In both cases, the starting point is a set of parallel load-bearing plates. Their role is to provide the necessary resistance to withstand loads.

In the case of pressed slats, the bearers are regularly notched to insert the cross bars (or spacers) which will be assembled at the very high pressure press. A frame is then firmly fixed by electrowelding.

For electroforged grating, the transverse bars are previously twisted squares that are embedded in the carriers (not notched) thanks to a very high pressure and simultaneously welded by electroforging. This process confers a very high rigidity to the grating and allows to cross it without altering its solidity.

Whether pressed or electroforged, the spacers allow the bearers to stay in place and obtain a rigid assembly.

Pressed grating: solid and stable interlocking

Here, the support bars are notched so that the spacers fit perfectly. Assembly is done under press. This is security, optimum stability. Why? the principle of this positioning makes it possible to obtain a grid with mesh distributed on a totally flat surface. The frame is made in the form of a T-profile or a flat and the whole is fixed by electrical welding. The load is equally distributed between the supports via the carrying bars. The stability is achieved thanks to the filling bars. The solution for high-strength grids. This technique is found in equipment for industry and for the construction of stairs for its non-slip properties for example. There are also half-iron slats, made of steel. The carrying bars here are the same height and notched up to half. The grating with stainless steel coating, will bring a hold against environmental elements such as water, steam or humidity, but also chemical reactions such as acids.

Electroforged grating: stiffness and torsional strength

The concept is based on transverse bars of twisted square profiles pressed and welded in a single operation on the supporting bars which are themselves not notched. This automated system offers a unique attachment with advantageous strength properties. Another asset, in the laying and the arrangement, the electroforged grating is cut without any risk of disassembly and retains all its primary qualities. This technical performance is perfectly in step with the requirements of large installations, with rigorous, normative and regulatory constraints.

Desirable technical properties in various applications

Thanks to its technical executions, the metal grating finds a perfect use in industrial, building and public works as well as logistics. By its visual rendering, the grating is also found in the cosmetic, food and pharmaceutical industry. It is also acclaimed by architects and planners, for its resolutely aesthetic approach, its modern lines and its freedom of an almost infinite layout, both for interior installations and for an exterior layout, and for its possible non-slip qualities.

For example, creating your stairs, gutter, flooring, shelf and many more.

If you would like to know more about our range of slats or if you are looking for a customized solution, do not hesitate to contact us.

Address: 134 Angle Route Ouled Ziane and Rue Aswane Immeuble B étage N° 3 , Casablanca 20250